Supply Chain Management: The Definitive Guide

- Saudi ERP & Website Solution Blog September 12,2023

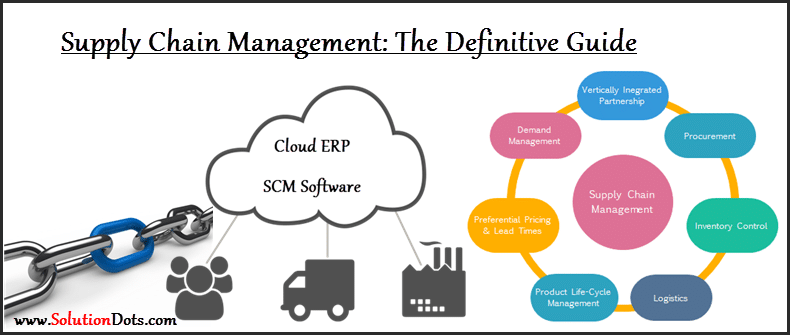

Supply Chain Management (SCM) is the flow of goods and services. It includes the movement and storage of raw materials, work-in-process inventory, and finished goods from point of origin to point of consumption.

In this guide we will show you the core points related to Supply chain management that you need to know is a new learner or an end user of Supply chain management System. All these points not only add knowledge to your mind, but they will also rectify lots misconceptions about the Supply chain management.

Top Chapters of Supply Chain Management

In the current environment of business changes rapidly, the companies have to face increasingly important demands for:

- Provide products and services faster

- With greater value added

- The correct location

- No relevant position inventory.

High levels of competition in the markets worldwide, has led companies to the conclusion that to survive and succeed in more aggressive environments, not just improve their operations and integrate their functions internal, it is necessary to go beyond the boundaries of business relationships and start sharing information, materials and resources with suppliers and customers in a much more integrated way, using innovative approaches that jointly benefit all actors in the supply chain.

Customers seek better quality, design, innovation, choice, convenience and service. Also they want to spend less money, making less effort and take fewer risks.

The supply chain of a company consists of different departments, from the procurement of materials to the service of attention to the client.

The management of the supply chain means the transformation of the "supply chain" of a company in the process optimal and efficient to meet the needs of the customer, where the efficiency of the entire supply chain is more important than the effectiveness of each individual department.

- Supply Chain Management (SCM) Definition

- DEFINITION OF 'SUPPLY CHAIN MANAGEMENT - SCM'

- Supply Chain Management Definition and Solutions

- What do we really mean by supply chain management?

- Module 1: What is Supply Chain Management?

A supply chain is a network of facilities and means of distribution whose function obtaining materials, processing of these materials into intermediate and finished products and distribution of these finished products to consumers.

A supply chain consists of three parts: the provision, manufacture and distribution.

The part of supply focuses on how, where and when are achieved and supply raw materials for manufacturing. The Manufacturing converts these materials into finished products and distribution ensures that these products reach the end consumer through a network of distributors, warehouses and retail stores. It is said that the chain starts with suppliers of your suppliers and customers end up with your customers.

STRATEGIC OBJECTIVE IN THE SUPPLY CHAIN

Increase the capacity of the participants to make decisions, formulate plans and outline the implementation of a series of actions aimed:

- The significant improvement in the productivity of the system operational logistics,

- To increase service levels to customers,

- In the implementation of actions that lead to a better management of operations and to a development of great benefit lasting relationships with suppliers and key customers in the supply chain.

- The Basic Concepts of Supply Chain Management

- The Most Important Concept in Supply Chain Management

- 7 Principles of Supply Chain Management Explained

- Supply Chain Management: Concepts, Techniques and Practices

A simple conceptual framework reveals flows and contexts where lies the mix of skills required in the company to integrate the logistics of the supply chain:

- The creation of value in the integration of the supply chain is achieved by simultaneous orchestration of four critical flows.

- To facilitate an effective and efficient flow in the supply chain, they must be integrated contexts related to the operation, planning and monitoring and behavior administrative.

1. SUPPLY CHAIN FLOW AS A SYSTEM

Flow value of the product –service

It represents the " movement "of the value added from the supplier of raw materials to final consumers.

Product value is increased through physical modifications, packaging, proximity physical to market , logistical posacabado for an adaptation of the product to the consumer, support service sales and after-sales and other activities that increase the "desirability" of the product from the point of view of end users.

Flow positioning in the market

It involves information concerning the sales and use of the product, which facilitates the planning of the supply chain. For example, requirements to adapt the product to the customer, data point of sale , consumption level of the final consumer and warehouse inventory status.

It should be noted that the flow of product placement on the market must provide the structure to support sales management, including claims.

This facilitates transparent flow actors in the supply chain the opportunity to display (when) and location (where) the consumption of the product. Remember that both planning and operation synchronizes best when all actors have a common understanding of the demand and consumption patterns.

Information flow

It is the bidirectional data exchange transactions and inventory status of actors / partners in the supply chain (eg: forecasts of sales / purchases , promotional plans, purchase orders, order validation, acceptance / credit orders, information inventory , shipping information -tracking & tracing-, invoices, payments and assortment requirements). Currently this flow is increasingly based on papers and is over character mail.

Cash Flow

It is generally inversely to the value-added activities, even in situations involving promotions and rebates flows in the same direction that the products.

The speed of the cash flow and the level of utilization of assets are critical to the performance logistics.

2. INTEGRATION OF THE SUPPLY CHAIN THROUGH A SYSTEM OF CONTEXT

To implement an effective and efficient integration of the supply chain should act systemically in three contexts: the operational, the planning and control and the "relational" of management.

The operational context

The operations resulting from the strategy pull attention to market: a process of order fulfillment and replenishment throughout the supply chain. Effective operation requires coordination both within the firm and between different actors / partners in the supply chain. That is, in this context operational integration is essentially internal, with customers and with suppliers.

Integration with the customer is built on the goal of creating "intimacy" with the consumer and leads to a competitive advantage to the extent that the specific logistic requirements of each customer segment are identified.

Internal integration focuses on the coordination of processes within the company related to procurement of resources and raw materials, manufacturing and physical distribution to final consumers.

With regard to internal integration many firms have made substantial efforts, but there are still many gaps and inconsistencies: Often the management of logistics has a better integration with suppliers with management of purchasing, production and marketing , sometimes purchasing management has better integration with suppliers with management of logistics, production and marketing.

Obviously the lack of internal integration is linked to an organizational structure and performance measures that emphasize traditional work "functional" and not "cross-functional" processes and equipment that are actually borne consumer satisfaction.

Integration with suppliers focuses on activities that create strong ties with partners in the supply chain, so that compact flow and rhythm established with the activities of working / manufacturing internal to the firm.

The company must make an appropriate mix of internal and open to suppliers that allow you to meet the increasingly high expectations of consumer demand closed processes.

Get a performance leader in the operational context requires the company to be focused on the consumer, constantly improve the matching process between functional levels and reach an inter-organizational coordination with suppliers of goods and services.

The context of planning and control

The context of planning and control refers to the design, implementation and coordination of information to improve purchasing processes, manufacturing, order fulfillment and resource planning. It implies access to databases that allow appropriate information sharing among participants and dedicated actors in the supply chain.

Furthermore, the leading firms involves systems to support decision-making for the utilization of production capacity, infrastructure and third parties- own equipment and for logistics in general and inventory operations.

The information technology systems and performance measures through the supply chain, are the basis for planning and control of integrated operations. Operational excellence is supported only by integrated planning capabilities and appropriate measurements, which involves linking technology to control overall performance of the supply chain.

The integration of information technology and indicators of performance measures should allow internal monitoring and conducting a benchmarking performance at a functional level and processes not only within the firm, but essentially the entire length of the supply chain .

As each company is unique, each must define, operationalize and monitor prior common Standards an adequately defined. Obviously, you need to create in the firm and its partners in the supply chain one culture of interorganizational management.

The "relational" context Management

Effective management relations are essential for the integration of the supply chain. The implementation of successful strategies of integration is based on the quality of business relationships established between actors / partners in the supply chain.

As general managers have been trained to handle relations competition rather than cooperation, we need a change in the systems of incentives to align throughout the supply chain.

There are no identical situations and therefore no recipe for effective management of the integration of the supply chain; however, certain principles seem basic, whether if it is the customers and suppliers of goods and services: a) specify roles, b) define guidelines for sharing profits and risks and solve conflicts c) establish what information should be shared.

- Making a Conceptual Framework for Supply Chain Management and Marketing Integration

- Supply Chain Management: An International Journal

- A New Framework for Supply Chain Management Conceptual Model and Empirical Test

Due to advances in manufacturing and distribution, it is lowering the cost of developing new products and services and accelerating the time to market . This has led to increased demands from customers, local and global competition and the pressure on the supply chain.

To remain competitive companies must reinvent themselves, so that the supply chain procurement and acquisition, planning production, order fulfillment, inventory management and customer care is no longer an exercise in cost-based back office, but a flexible operation designed to deal effectively to today's challenges.

Internet is proving to be an effective tool in transforming supply chains of all industries . Suppliers, distributors, manufacturers and retailers are now working more closely and effectively than ever.

The current supply chain controlled by technology, enables customers to manage their own shopping experiences, enhanced coordination and connectivity between supply partners and help reduce operating of each of the companies in the chain costs.

- The Evolution and History of Supply Chain Management

- History & Academic Definition of Supply Chain and Logistics Management

- A brief history of modern supply chain management and best practices

- Six Global Supply Chain Predictions for 2015

- Five Procurement Predictions for 2015

Management of Supply Chain is planning, organization and control of the activities of the supply chain. These activities cash flows management, product or service information is involved, throughout the supply chain, in order to maximize the value of the product / service delivered to the end consumer while diminish costs of the organization .

The management of the supply chain (SCM - Supply Chain Management) can also be defined as the term used to describe the set of production and logistics processes whose ultimate goal is the delivery of a product to a customer. This means that the supply chain includes the activities associated from obtaining materials for the processing of the product, to its placement on the market.

The Supply Chain Management is, ultimately, to form alliances and stable relations among all members, from suppliers to suppliers to customers of customers. However, to achieve a synchronized supply chain is not enough to undertake isolated actions in this regard. It should go further and develop a joint strategy to provide benefits to all members and cover the following aspects:

- Development of skills themselves that are based on the expertise of the company, hiring experts those processes in which the company is not a specialist. The competences be developed considering the continuous process improvement and total quality management.

- Strategic cost management defining strategies to reduce the total cost of the chain (for example, taking advantage of synergies) instead of moving a few links to others in the chain.

- Fast and reliable exchange of information through a clear implementation of systems and information technologies. This information must allow knowledge all customer needs.

- Effective management of the physical flow of materials , considering issues related to the cost of transportation , time and speed of response in developing strategies related to the supply chain.

- Rating results,defining key indicators and mechanisms of common and appropriate valuation that adequately control the critical success factors.

The benefits that companies can obtain through an integrated supply chain management are really important. The following are some of the major improvements that can lead this effort:

- Increased income : 5% -25%

2. Inventory Reduction: 25% -55%

3. Improved productivity of staff : 25% -75%

4. Improved delivery time: 25% -60%

Noting the above data seems logical that many companies will be part of integrated supply chains to benefit from all the improvements described. However, this is not reality. The project management of supply chains are complex, requiring high levels of trust and collaboration among members and do not always produce the expected results. We discuss in more detail each of these aspects:

- Complexity. The companies that have achieved higher profits through supply chain management have made significant efforts to determine the status of all links in the chain and identify the model that benefits more to all concerned.

- Trust and cooperation. These projects require a lot of relevant information of participating companies (for example, sharing their objectives strategic) and, on the other hand, require intense collaboration by all involved.

- Uncertainty. The success of these projects is uncertain and often consumes more time than planned and are exceeded budgets starting to finally not fully meet expectations.

However, despite these difficulties, each company must evaluate rigorously, together with its suppliers and customers, the possibility of an integrated management of the supply chain and the potential of this type of management can compensate competitive advantages wide effort to perform.

- 7 Principles of Supply Chain Management Explained

- Principles of Supply Chain Management Stand the Test of Time

- What are the benefits of Supply Chain Management (SCM)?

- The Advantages of Supply Chain Management Systems

Andersen Consulting has proposed a list of seven principles for the management of the supply chain, based on the experience of initiatives to improve the supply chain in more than 100 industrial companies, distributors and retailers.

The implementation of these principles can balance the needs of customers excellent service to the requirements of profitability and growth. In determining what customers want and how to coordinate efforts throughout the supply chain to meet these demands faster, cheaper and better.

Principle No. 1:

Segment your customers based on the service needs of different groups and adapt the supply chain to serve these markets profitably.

We have traditionally segmented customers by industry , product or sales channel and we have given the same level of service to each customer within a segment.

An efficient supply chain brings together customers for their service needs, regardless of what industry you belong to and then adapts the services to each of these segments.

Principle No. 2:

Adapt the network of logistics service requirements and profitability of customer segments.

When designing the logistics network must focus intensely on service requirements and profitability of the identified segments. The conventional approach to create networks monolithic contrary to the successful management of the supply chain.

Even thinking about unconventional logistics emerge in certain industries that share customers and geographical coverage resulting in redundant networks. When changing complementary and competitive logistics industry under the ownership of other companies, savings can be achieved for all industries.

Principle No. 3:

Watch for the signals of the market and align demand planning accordingly with the whole supply chain, ensuring consistent forecasts and optimal resource allocation.

The sales and operations planning must cover the entire chain, seeking early diagnosis of changes in demand, detecting patterns of change in processing customer orders promotions, etc.

This intense focus on demand leads to more consistent forecasts and optimal resource allocation.

Principle No. 4:

Look differentiate the product as close to the customer.

It is not possible to accumulate inventory to compensate for errors in sales forecasts. What we must do is to postpone product differentiation in the manufacturing process as possible about the end customer.

Principle No. 5:

Strategically manage the sources of supply.

By working more closely with key suppliers to reduce the cost of materials and services, we can improve margins both for us and for our suppliers.

The concept of squeeze suppliers and make them compete is not the way to proceed, now the trend is "win-win".

Principle No. 6:

Develop a technology strategy for the entire supply chain.

One of the cornerstones of a successful management of the supply chain is the technology of information that must support multiple levels of decision-making and provide a clear view of the flow of goods, services, information and funds.

Principle No. 7:

Adopt performance measures for all channels.

Systems of measurement in supply chains serve to monitor internal functions, measurements that apply to each of the links in the chain should be taken. The most important thing is that these measures contain not only financial indicators , but also help us to measure service levels, such as the profitability of each customer, for each type of operation, business unit, and ultimately, for each I asked.

These principles are not easy to implement, and require certain skills which in some cases are not naturally found in the logistics professionals. It requires an effort group , multifunctional skills, with ace, quality facilitators integrate the divergent needs of manufacturing and sales, quality and price , cost and service and the qualitative and financial measures.

It should broaden understanding of the other areas of the organization has to improve knowledge of the functions of purchasing, product planning, marketing , sales and sales promotion , and must also develop a more intimate knowledge of their clients.

Remember that the supply chain begins and ends with the customer.

Additionally, it is important for professionals to be knowledgeable about information technology. The information is not a function in addition to the supply chain, rather the enabler support, the means by which integrate several links in a single chain.

First it must support operational activities, decision making short-term management of daily transactions, order processing, shipments, movements of stock , etc. Second, it must support the planning and decision making medium-term support as demand planning, the programming master of production, and in general the optimal allocation of resources.

Finally, information systems must support the analysis to provide strategic tools of modulation and other tools that synthesize data for planning scenarios, help management to evaluate the distribution centers, suppliers, outsourced services, etc.

The integration of the supply chain is not new, many large companies have made efforts to build an architecture that enables them to gain technological competitiveness .

There are four key fronts in which new technologies can help for a better management of the supply chain:

- Information Integration.

- Synchronized planning.

- Coordinated work flow.

- New models of business.

- Integration of information

Sharing information is a key element for proper chain management. We must be willing to share all information that is important for decision-making, such data demands of customers, the state of the warehouse inventory, time and production schedules, plans promotion or shipping dates.

To ensure that the supply chain is being targeted based on consumer demand, information sharing is crucial. It is the method most effective to detect a problem of distortion of forecasts in the chain.

A chain distortion arises when a company has a production forecasts made from multiple factors, and fails. These errors of calculation cause a ripple effect that drags the other members, and are considered the major cause of the inefficiency of a supply chain.

The industry of food is one of the sectors where the transparency of information is vital for proper management. In power must know how to respond correctly to the ups and downs of food, and for that many companies share sales information, statistics inventory, software production, promotion plans, and demand forecasting.

Synchronized planning

Having achieved that members of the supply chain to share information, the next step is to plan what to do. By synchronized or collaborative planning we mean design and implementation of plans for the introduction of a product on the market, forecasting and replenishment. The ideal scenario is that all members who are part of the chain to take part in strategic decisions about the product.

For example Adaptec, a US technology company, used application software called Alliance management (developed by Extricity), allowing you to communicate with their offices Califormia design, its factory in Taiwan, its plant assembly in Japan , Hong Kong and Singapore, exchanging detailed schemes of new prototypes, test results, and share production and shipment dates provided. This information greatly facilitated their ability to respond adequately to the demand of industry semiconductor and reduce development time for new products.

Coordinated workflow

The members of a supply chain must decide how to work in coordination by establishing automated activities to ensure the smooth running of the chain. The more engaged you are a team of companies in procurement activities from the supplier to the manufacturer, better results in terms of accuracy, cost and time they can get.

Get supplies for product creation can be a headache to meet deadlines. By using the Internet , companies can conduct shopping complex tasks, from the budget request, decision making, purchase order, order confirmation, etc. Tasks that usually delayed in day operations of the Purchasing Department, today can be resolved in hours.

New business models

The adoption of new technologies in the management of supply chain have proven to contribute ideas to the companies that use them to give quickly to new business opportunities than before, due to the long process involved in the chain, they were impossible to perceive.

An example is the accumulated stocks that have failed to be sold. Through solutions like SoloStocks.com Internet portal, they can have a second chance on secondary markets, minimizing inventory obsolescence, and losses for the company.

Another way to take advantage of new technologies in a chain

Supply are:

- The restructuring of the logistics operations to gain efficiency : the implementation of supply chain supported by Internet can open our eyes to many physical processes that can be avoided with proper online control.

- Product Update : less time in the chain is less development time and easier to update a product. The software industry is one of the most surprising us with constant updates resulting from errors in production, which once detected are corrected quickly.

- Improvements in the post-sale service and support : Internet can help reduce costs of maintenance of a service department and customer support.

Greater efficiency in the negotiations thanks to the possibilities of new technologies in information exchange with suppliers.

- Greater control in managing suppliers. They can be accessed at a higher number of potential suppliers to a greater number of offers quick, easy and automated way.

- Cost reduction from 20% to 30%. The integration of a supply chain can dramatically reduce operating costs.

Decrease provisioning time by communicating in real time with suppliers. - Improved inventory management. Online information supplies in warehouses allows to foresee the needs of production and optimize inventory management.

- Monitoring supply deadlines, production schedules, and shipping dates, which ensures greater ability to respond to market demand.

1. The Administration of Supply Chain often requires the improvement and redesign of business processes to adapt to market changes and demands and preferences of its customers, for shorter, faster and more accurate cycles.

2. Proper management of the supply chain would bring numerous benefits, ensuring effectiveness in negotiations thanks to the possibilities of new technologies in information exchange with suppliers. These technologies allow access to a greater number of potential suppliers and even greater number of offers quick, easy and automated way.

3. Furthermore, the integration of a supply chain can dramatically reduce operating costs and significantly improve its financial performance and competitiveness through a range of processes: planning and scheduling, supply and management of information and materials and administration costs associated.

The supply chain is as strong as the weakest link of it. To develop and implement strategies Supply Chain integrates and manages its business partners (or the extended proc ess).

- Introduction to Supply Chain Management

- Supply Chain Management in Retail training tutorial video

- Advance Your Career With APICS Certifications

- 3 Supply Chain Certifications That Will Help You Land a Job

- Become an Expert With Credentials From the #1 University for Supply Chain Management – 100% Online!

Saudi Arabia (English)

Saudi Arabia (English) United Kingdom

United Kingdom Global Site

Global Site