Top 5 Benefits of Supply Chain Management Software That will Double Your Business

- Blog August 22,2023

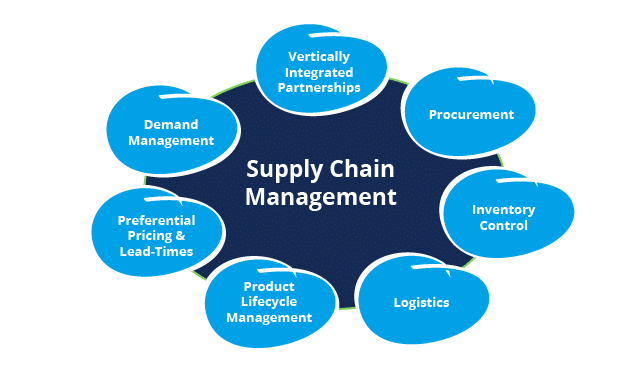

Supply chain management, put simply, is actively managing the various moving parts of a supply chain while aiming for max customer satisfaction, lower costs and competitive advantages.

Within the past, each section of a supply chain was a self-contained problem handled by people who directly interacted with it.

Nowadays, the availability chain is, correctly, viewed as an interconnected series of pieces that employment together to manufacture and deliver products to customers accurately and quickly.

When a business has an efficient supply chain management, it’s a competitive advantage in its industry that permits you to decrease the inherent risks when you’re buying raw materials and selling products or services.

Benefits of Supply Chain Management System

Supply chain management software systems do tons for businesses in industries across the planet. SCM tools can automate much of the physical supply chain process and supply analytics and business intelligence for growth.

Supply chain management systems help human leadership teams fine-tune business operations and make them as efficient and effective as possible, for a competitive advantage during a particular industry.

- Better flow of materials, products and knowledge.

- Decrease cost effects.

- No more delays in processes.

- Demand forecasting.

- Cloud-Based Benefits.

Most of the time supply chain management flow is split into 3 basic flows that are:

- The Product Flow

- The Information Flow

- The Finances Flow

Now that we all know the availability supply chain management flow allows us to discuss intimately the advantages of supply chain management systems.

- Better flow of materials, products and knowledge

Supply chains are all about flow. Put simply, supply chains are always chasing after shorter times between manufacturing a product and getting it bent the customer that ordered it. Achieving this needs quite few variables that has got to even be running at maximum efficiency to urge these delivery times down.

- Decrease cost effects.

One of the benefits of supply chain management is that the costs decrease in several areas. The foremost important ones are:

- Improves your inventory system;

- Adjusts the space for storing for finished goods which eliminates damage resources;

- Improves your system’s responsiveness to the particular customer’s requirements;

- Improves your relationship with both distributors and vendors.

- No more delays in processes

One of the most benefits of supply chain management is that the incontrovertible fact that through communication, you’ll actually lower any delays in processes.

Since most are conscious of what they’re doing also as what others do, this may mitigate any late shipments from vendors, logistical errors in distribution channels, and hold-ups on production lines.

- Demand forecasting

Demand forecasting forms an important component of the availability chain process. It is the driver for nearly all supply chain related decisions. Demand Forecasting defined because the process by which the historical sales data are to develop an estimate of the expected forecast of customer demand.

- Cloud-Based Benefits

With the increase of cloud-based computing, maintaining software and sophisticated IT infrastructure are often taken out of the equation. Updates and upgrades to your SCM system are available in real-time without slow-down or costly time spent upgrading station after station.

Not only that, but as technology continues to enhance, we see helpful additions like mobile access being included in additional and more systems. Now, supply chain managers are often on the move while still being connected to the vital processes of the day.

Saudi Arabia (English)

Saudi Arabia (English) United Kingdom

United Kingdom Global Site

Global Site