Supply Chain Management in Saudi Arabia

- ERP (Cloud) September 26,2023

Are you seeking Supply chain Management in Saudi Arabia?

Don’t worry about it! our company offers the best Supply chain Management Solution for Saudi Arabia.

SolutionDots offers the Best SCM Software for your Business. With a lot of features

How to Choose Supply Chain Management

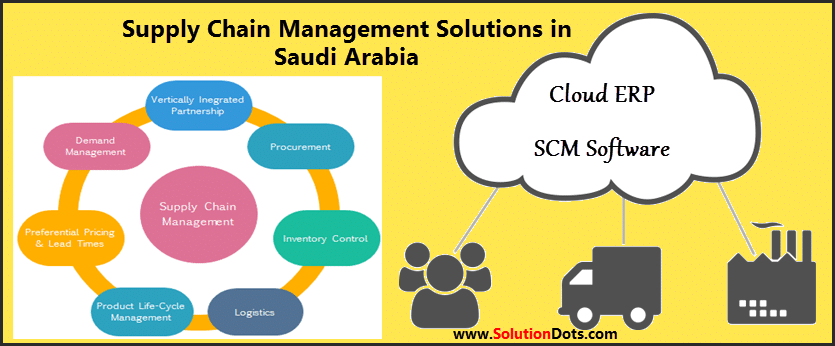

The term SCM (management of supply chain, supply chain management) refers to the tools and methods whose purpose is to improve and automate the supply through the reduction of inventories and delivery times.

SCM tools rely on data regarding production capacity stored in the company’s information system to automate order placement. These tools are closely integrated with the organization’s overall management framework, particularly Enterprise Resource Planning (ERP).

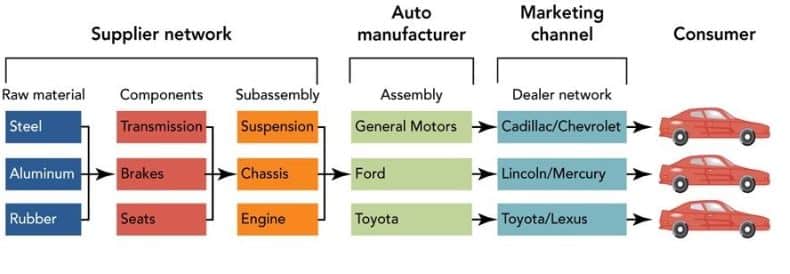

In theory, a SCM tool allows you to track the passage of pieces (traceability) between the different participants in the supply chain. Management Solution for Automotive Supply Chain SolutionDots (SD) provides a set manufacturer and supplier of tools needed to manage the supply cycle, from the first set of requirements to ongoing monitoring and performance improvement.

The solution offers a framework that categorizes the supply chain based on different profiles, including provider structure, geographic location, and operational capabilities. With this framework established, OEMs can effectively communicate their needs and meet supply chain requirements.

- Specifications and other pertinent data should be shared in real-time.

- This improves communication and understanding among potential suppliers, facilitating a better negotiation process.

- The selection of suppliers is one of the most fundamental and difficult decisions in the development process.

SolutionDots System allows the buyer to collect data for comparison and effective study and determine acceptance criteria for an objective view of the collections supplier responses.

In the automotive sector, the supply process continues beyond contract awards, requiring the exchange of critical data. The SD solution fosters ongoing collaboration between OEMs and suppliers throughout development, ensuring steady production rates and minimizing misunderstandings.

Change requests are processed, scorecards are revised, and quality plans are created in collaboration with OEMs and suppliers. Performance history guides future supply efforts, ensuring the supply chain is ready for successful deployments and product launches.

The Automotive Supply Chain Management Solution Includes:

- Management database suppliers

- Management of tendering and e-RFx

- Contract management

- Development, evaluation, and management of the supply base

- Management simultaneous style

- Library management for parts

- Management, reuse, and usage tracking parts throughout the lifecycle

- Reports on materials

- Collaboration PPAP / supplier

- PPAP / PSW (approval process for production parts/guarantee shipment of parts to the customer)

Saudi Arabia (English)

Saudi Arabia (English) United Kingdom

United Kingdom Global Site

Global Site