Best Production Planning Software Guide : Step By Step

- ERP (Cloud) September 19,2023

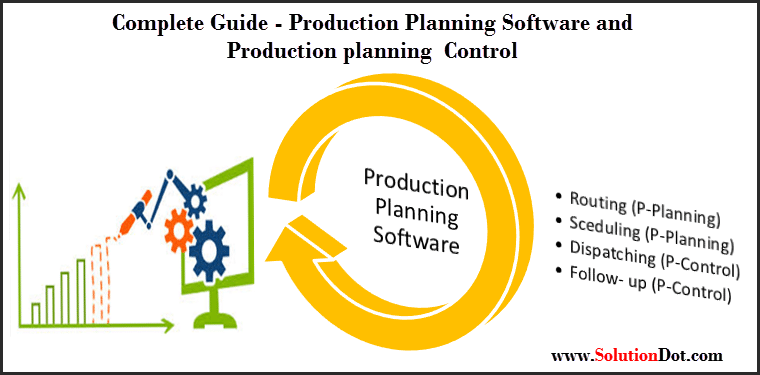

Production planning software streamlines resource allocation, optimises scheduling, improves efficiency, and enhances overall productivity for manufacturing and production processes. I’ve aimed to cover all relevant points related to production planning software to provide you with a comprehensive overview.

Top Production Planning Software’s

What is Production Planning Software

Purpose of Production Planning Software

Objectives of Production Planning Software

Benefits of Production Planning Software

Why Production Planning Software and Production Planning & control (PPC) are essential for operating unit

Fundamentals problems solved by Production Planning Software function PPC

Benefits of using Production Planning Software and PPC

All these points will not only add knowledge to your mind, but they will also rectify lots misconceptions about the Production Planning Software.

Here are Top Chapters of Production Planning Software.

Production Planning is the process of establishing an overall level of output, called the production plan. Planning is essential for firms to work in an efficient way to control every aspects of business.

Planning always fails due to lack of uncertainty in vision, objectives, goals and inadequate preparation. Business firms use different types of Production Planning Software to do all their operations and tasks.

By using Production Planning Software we can manage that what work should be done and how much time will be taken to perform work tasks.

“Production Planning Software is essential for scheduling, dispatch, inspection, quality management, supply management, equipments management and inventory management.“

The Production Planning Software is an enterprise resource planning (ERP) solution that firms need to meet with basic concepts of what to produce, how much need to produce and when to produce etc.

Firms need to build production planning strategies in order to meet demands forecast. Carefully developed production planning software allows companies to minimize cost, inventory, production rates, employees and maximize utilization of plant, equipment’s and customer services.

- Production Planning Software ensures that at the time of production right quality and quantity of raw materials, equipment’s etc. are available to complete production process.

- Production Planning Software ensures that utilization of resources is always ready to meet forecast demands all the time.

Numerous ERP solutions for production planning are available in the market today. Below are some key objectives of these systems:

- Utilization of resources effectively

- Flow of Production

- Estimation of resources

- Optimum inventory

- Coordination of department’s activities

- Minimize consumption of raw materials

- Improves productivity of labor

- Market competition

- Ideal work environment

- Quality improvement facility

- Consumer satisfaction

- Reduce production cost

Top 12 Objectives of Production planning software

The primary goal of production management tools is to reduce production time and costs while maximizing workplace efficiency. Let’s explore each objective in detail:

1. Utilization of Resources Effectively

Resource management tools enable firms to optimize their resources efficiently and effectively, leading to increased returns for the organization.

2. Flow of Production

Production Planning Software ensures a steady flow of production within an organization. That all its components are working and supply to customers is up to date.

3. Estimation of Resources

Production Planning Software helps to estimate various resources like men, materials, machinery etc. By monitoring sales, we can plan production according to our sales.

4. Optimum Inventory

Production Planning Software ensures optimum inventory and prevents over stocking or under stocking. Raw material is maintained properly to meet production demands any time and other necessary stocks are also maintained to fulfill needs.

5. Coordination of Department’s Activities

Production Planning Software helps to coordinate all departments of a firm with each other i.e. marketing department coordinate with the production department to sell goods.

6. Minimize Consumption of Raw Materials

Production Planning Software minimizes wastage of raw materials and ensures the production of quality products.

7. Improves Productivity of Labor

Production Planning Software improves labor productivity and maximized utilization of manpower. Training is provided to the workers and profits are shared with workers inform of increased wages & incentives.

8. Market Competition

Production Planning Software helps to give delivery of goods in time to customers and it’s all because of regular flow of quality production. So a company can survive in the market and compete with others.

9. Ideal Work Environment

Production Planning Software provides better work environment for to its workers. Workers get better working conditions, proper working hours, leaves, holidays and increase in wages plus other incentives because the company is working efficiently.

10. Quality Improvement Facility

Production Planning Software assists quality improvements because production is checked on a daily basis. Consciousness of quality is groomed in workers through proper training sessions and counseling.

11. Consumer Satisfaction

Production Planning Software helps to give a regular supply of goods and services to its consumers at fair prices. Because of good services it results in consumer satisfaction.

12. Reduce Production Cost

Production Planning Software allows firms to optimum utilization of their resources and wastage. The software helps to maintain inventory sizes optimum and reduce production costs ultimately. Read Top 5 Advantages of Supply Chain Management.

Production Planning Software ensures that whole production process is streamlined and provides following benefits to firms are mainly these below:

- Software facilitates organizations to deliver end products in a regular manner in given time span.

- Software reduces the investment of inventory.

- It reduce overall firm’s production cost of driving in efficiency.

- Firms who are using software can alert its suppliers in advance for required raw materials

Read 27 Benefits of ERP Implementation in Your Organization.

Production planning and control both are essential for success of an operating unit. The benefits of production planning & production planning and control (PPC) are as follows

- Manage all the operations in a manufacturing unit of an organization.

- Ensure that inventory stock is not over stock or either under stock and keeps it at an optimum level of time by production planning and control (PPC).

- Firm’s use Production Planning Software and PPC to increase the turnover time because it ensures that production time is kept at optimum levels.

- Ensure that the production team will achieve production targets in time.

- Optimize the utilization of resources, quality management and cost savings.

- The main purpose of Production Planning Software and PPC is to low productivity, inventory and resource utilization.

- Check all aspects of production process and also maintained the quality of final product always.

Production Planning Software and production planning & control (PPC) solve major problems of firms from starting point to till end product result. Hurdles solve by Production Planning Software are described below, check it out.

1. Materials

Production Planning Software function PPC ensured that the raw materials, standard finishing parts of the products must be ready while production department need them.

2. Methods

Manufacturing planning tools and PPC focus on analyzing production methods. These solutions offer effective strategies and support in challenging situations.

3. Equipments & Machines

Effective tools ensure that manufacturing processes align with available production facilities. The planning and control function focuses on analyzing production capabilities while maintaining procedures and equipment policies.

4. Routing

Production Planning Software and (PPC) manage the sequence of operations and processes that are followed in producing particular finish products. PPC resolve issues in manufacturing operations and sequence facing hurdles.

5. Estimation

The function of production planning and control (PPC) focuses on estimating operational timing. When a firm effectively manages methods and the sequence of operations, a PPC process sheet is available for each step of the operation.

6. Scheduling & Loading

The system ensures that machines are utilized based on their capacity and capabilities. The planning and control component addresses the preparation of machine loads, setting deadlines, and completing specific operational tasks effectively.

7. Dispatching

Planning and control tools assist firms in completing order tasks on time, ensuring that the final product is ready for dispatch after thorough inspection and evaluation.

8. Inspection

These tools also offer inspection features, which are essential for planning and control (PPC). After dispatching the final product, assessment is crucial to maintaining the firm’s quality and reputation.

9. Evaluation

The PPC function offers evaluation capabilities to manage key operational components effectively. By utilizing a feedback mechanism over time, past experiences can be assessed, leading to improvements in resource utilization and facility management.

Organizations can enjoy several benefits when utilizing resource management tools and production planning and control (PPC) practices, including:

- Regulate inventory management and organize production schedules.

- Optimize utilization of resources and production process.

- Ensured the smooth flow of production processes

- Improve bottom line saves production cost.

- Control wastage of resources.

- Make standards of quality through the production life cycle.

Planning tools and production control methods can vary significantly across organizations, depending on whether their focus is job-oriented, service-oriented, or otherwise. The nature of operations and the size of the organization also play crucial roles in determining the best approach.

Enterprise resource planning systems for small to large businesses facilitate growth by minimizing costs and boosting profitability. These tools have become essential for production companies today.

When you start a business, you need to manage all activities manually but don’t worry about these problems because you can manage your business with the help of ERP Production Planning Software.

This list of Production Planning Software will give you idea of the production process and control of every aspect related to production or manufacturing. Now all you need is to compare a list of top 5 Production Planning Software’s with your business type check it out:

1. E2 Shop System Software

E2 by Shoptech Corporation is an ERP solution that oversees all business operations, including estimating, scheduling, purchasing, shipping, customer management, and accounting. This software supports the Windows operating system and is designed for small to midsize companies.

2. Cloud ERP Based Supply chain Management System (SCM)

Supply Chain Management (SCM) developed by SolutionDot is an ERP solution designed for effective production management. The SCM system offers comprehensive solutions for accounting, business intelligence, CRM, human resources, inventory, manufacturing, and project management. It primarily targets small and midsized businesses, providing the tools they need for streamlined operations.

3. FishBowl Manufacturing

Fishbowl manufacturing ERP is tailored for small to midsized companies seeking a comprehensive inventory management solution. This system is compatible with Windows, Mac, and Linux operating platforms.

4. ExactJobBOSS Software

Exact JobBOSS ERP is designed for quoting, planning, and manufacturing execution systems. This tool is primarily adopted by small and mid-sized businesses and supports Windows operating platforms.

5. SAP- Manufacturing Software

Founded in 1972, SAP’s manufacturing ERP offers solutions for over 100,000 businesses globally, catering to organizations of all sizes. This tool seamlessly integrates with all manufacturing operations and is compatible with Mac, Windows, and Linux platforms.

In conclusion, ERP systems have introduced innovative methods for addressing challenges in production units. Practices for planning and control vary significantly among organizations and plants. This software empowers manufacturers to set ambitious goals and achieve new heights.

By automating production processes, ERP solutions improve efficiency. This article highlights the necessity of these tools, as organizations aim to reduce costs, save time, and maximize workplace efficiency.

Read The Definitive Guide of Supply Chain Management.

In this article you can also see key objectives of Production Planning Software and with description. Advantages and objectives of production planning & control (PPC) and how Production Planning Software and (PPC) both work within an organization for its benefit.

Regardless of size and type many Production Planning Software are available in the market for every organization. You can easily choose the best Production Planning Software, ERP suite for your own business from small sized to large.

For more Technological Guide Information…Stay Connected with SolutionDot!

Saudi Arabia (English)

Saudi Arabia (English) United Kingdom

United Kingdom Global Site

Global Site